What is Distribution Board?

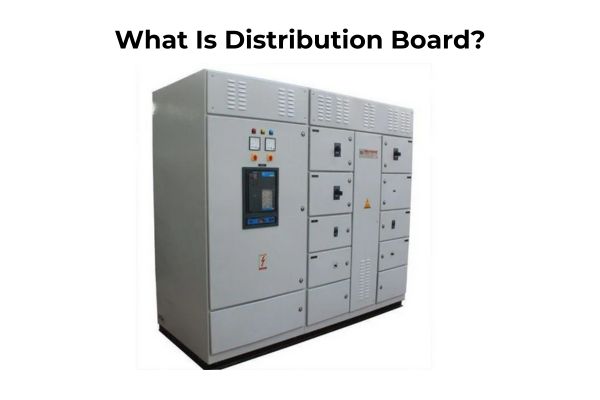

A distribution board is a critical part of an electrical system that manages and distributes electricity to multiple circuits. Used in industries, offices, and homes, it consists of circuit breakers, busbars, and fuses to ensure power safety and efficiency.

Introduction

A distribution board is a critical part of any electrical system, ensuring that power is efficiently allocated across different circuits. It acts as the central hub for managing electricity in homes, offices, and industrial facilities, helping to prevent overloads, short circuits, and electrical hazards. In this blog we cover its importance, components, types of distribution board.

What is a Distribution Board?

A distribution board is the main control unit of an electrical system, where electricity from the main power supply is divided into different circuits. It ensures that each circuit receives the appropriate amount of power while preventing electrical faults, overloads, and short circuits.

Often referred to as an electrical DB, this unit consists of circuit breakers, fuses, and residual current devices (RCDs) that regulate and protect the electrical network. The use of a distribution board is essential for maintaining organized power distribution, ensuring that electricity is safely delivered to lighting systems, appliances, and industrial machinery.

Designed for both residential and industrial settings, a distribution board enhances electrical safety by isolating faulty circuits without disrupting the entire power supply. This helps in efficient power management and long-term system stability.

Why is a Distribution Board Important?

1. Ensuring Safe Power Distribution

A distribution board functions as a protective barrier between the main power supply and various electrical circuits. It regulates the flow of electricity, ensuring that each circuit receives the right amount of power without overloading. This prevents short circuits, overheating, and potential electrical fires, making it an essential component in any electrical setup.

2. Overload and Fault Protection

Inside an electrical distribution board, there are circuit breakers, fuses, and residual current devices (RCDs) that monitor the flow of electricity. When an overload or fault is detected, these safety devices automatically disconnect power, protecting appliances and preventing damage to electrical wiring.

3. Organized and Efficient Power Management

A well-installed distribution board ensures that power is allocated efficiently across multiple circuits. This is especially important in industrial environments, where heavy machinery and electrical equipment require stable power distribution.

An industry distribution board helps prevent voltage fluctuations, ensuring that each section of an industrial facility gets reliable and consistent power.

4. Compliance with Electrical Safety Standards

Modern electrical distribution boards are designed to meet safety regulations, ensuring that electrical systems operate within safe limits. This is critical in industries, where compliance with electrical safety codes is mandatory to avoid legal issues and workplace hazards.

5. Versatility for Different Applications

From residential buildings to large industrial plants, distribution boards are adaptable to different power needs. They allow users to add new circuits or upgrade electrical systems without disrupting the entire setup. This makes them an essential part of modern electrical infrastructure.

A well-designed distribution board not only enhances safety and efficiency but also provides peace of mind by ensuring that electricity is distributed securely and effectively.

Industries That Require Distribution Boards

Different distribution board types are used across industries to ensure efficient power management and safety. Some sectors rely on them for uninterrupted power, while others need them to handle heavy electrical loads. Here’s how various industries benefit from a well-structured distribution board system:

1. Manufacturing Plants

Factories and industrial units require consistent power distribution for heavy machinery, automated production lines, and processing units. A distribution board helps prevent overloads and short circuits, ensuring that each section receives the required power without disruptions.

2. Construction Sites

Since construction projects need temporary power setups, a distribution board allows site managers to control power flow to different tools and equipment. It helps maintain safety and efficiency in ever-changing work environments.

3. Hospitals & Healthcare Facilities

A reliable power supply is essential for critical medical equipment, including ventilators, imaging machines, and emergency lighting. A distribution board ensures continuous and stable electricity, reducing the risk of system failures in life-saving situations.

4. IT & Data Centers

Data centers house high-performance servers that require uninterrupted power. A distribution board helps regulate power distribution, preventing voltage fluctuations that could damage sensitive electronic systems.

5. Commercial Buildings & Offices

Businesses and office spaces need controlled power allocation for lighting, HVAC systems, computers, and security setups. A distribution board enables power segmentation, ensuring different departments and floors receive electricity as needed.

6. Industrial Warehouses

Warehouses operate automated storage, conveyor belts, and refrigeration units, all of which demand stable electricity. A distribution board helps manage multiple electrical loads efficiently, preventing system failures and downtime.

7. Retail Stores & Shopping Malls

Retail environments use lighting, security systems, billing machines, and refrigeration units that require balanced power distribution. A distribution board ensures that essential electrical functions run smoothly, enhancing operational stability.

Industries which require industry distribution board systems rely on them for organized power flow, safety compliance, and uninterrupted operations. Selecting the right distribution board types ensures businesses run efficiently while preventing electrical hazards.

Components of a Distribution Board

A distribution board is made up of multiple components that work together to ensure safe and efficient power distribution. Different distribution board types may have variations in design, but the core components remain essential for functionality.

1. Circuit Breakers

Circuit breakers protect electrical circuits from overloads and short circuits. They automatically shut off the power when they detect an excess current, preventing damage to appliances and reducing fire hazards.

2. Busbars

Busbars are metallic strips that distribute electricity from the main supply to individual circuit breakers. They allow efficient power flow and help manage multiple circuits within a distribution board.

3. Enclosure (DB Box)

The enclosure is the protective housing that holds all the components together. It is designed to shield the internal wiring from dust, moisture, and physical damage, ensuring long-term durability.

4. Residual Current Devices (RCDs)

An RCD is a safety device that cuts off the power supply if it detects a leakage current. This helps prevent electric shocks and enhances overall safety in homes and workplaces.

5. Neutral and Earth Bars

These components allow for proper grounding and neutral connections, ensuring stable power flow while reducing the risk of electrical faults.

6. Main Switch

The main switch controls the overall power supply to the entire distribution board. It allows users to manually turn off power when necessary, making it an essential safety feature.

Choosing a high-quality distribution board from a trusted electrical panel manufacturer in India ensures reliability, durability, and compliance with safety standards. Well-structured components not only enhance efficiency but also reduce the risk of electrical failures.

Types of Distribution Boards

Different distribution board types are designed to meet the power needs of homes, commercial buildings, and industries. Choosing the right type depends on power requirements, safety features, and installation settings.

1. Main Breaker Panel

The main breaker panel controls the entire power supply for a building. It includes a main switch that can shut off electricity to all circuits at once. This type is commonly used in residential and industrial setups where complete control over power distribution is necessary.

2. Subpanel

A subpanel is an extension of the main breaker panel. It helps distribute electricity to specific areas, such as separate floors, additional buildings, or large industrial sections. This setup allows for better load management and prevents overloading the main panel.

3. Fuse Box

Older electrical systems often use fuse boxes instead of circuit breakers. When there is an electrical fault, the fuse melts and disconnects the circuit to prevent damage. While still found in some homes and small businesses, they have largely been replaced by modern circuit breaker panels.

4. Industrial Distribution Board

Industries which require industry distribution board solutions often use customized panels designed to handle high voltage loads and heavy machinery. These boards are equipped with multiple safety mechanisms, such as overload protection, surge suppressors, and emergency shut-offs, to prevent electrical failures.

5. Power Distribution Unit (PDU)

A PDU is commonly used in data centers and IT environments. It ensures even power distribution across multiple servers and networking equipment, reducing the risk of power surges and downtime.

The choice of a distribution board depends on the specific electrical needs of a location. Whether for homes, offices, or industrial sites, selecting the right distribution board type ensures safety, efficiency, and long-term reliability.

How to Choose the Right Distribution Board?

Selecting the right distribution board is crucial for safety, efficiency, and long-term reliability. Whether for residential, commercial, or industrial use, several factors must be considered before purchasing from a distribution board supplier or an electrical panel manufacturer in India.

1. Load Capacity

The first step is determining the power load the distribution board will handle. For homes and small offices, a standard single-phase board may be sufficient. However, for factories and large buildings, a three-phase distribution board is recommended to manage higher electrical loads.

2. Type of Distribution Board

There are multiple distribution board types, including main breaker panels, subpanels, and industrial distribution boards. The choice depends on whether the installation is for general power distribution, a dedicated section, or high-load industrial applications.

3. Material and Durability

A high-quality enclosure made of stainless steel or durable plastic protects internal components from moisture, dust, and corrosion. The distribution board should be fire-resistant and weatherproof, especially for outdoor or industrial use.

4. Safety Features

A reliable distribution board should include circuit breakers, residual current devices (RCDs), and proper grounding mechanisms. These features protect against overloads, electrical faults, and short circuits, reducing the risk of fire hazards and system failures.

5. Compliance with Electrical Standards

Always choose a distribution board that meets national and international safety regulations. An electrical panel manufacturer in India should provide products that comply with IS (Indian Standards), IEC (International Electrotechnical Commission), and BIS (Bureau of Indian Standards).

6. Scalability and Future Expansion

If there are plans for future electrical upgrades, selecting a modular distribution board with additional circuit slots ensures flexibility. This allows new circuits to be added without replacing the entire board.

7. Manufacturer Reputation

Buying from a trusted distribution board supplier ensures the product is high-quality, tested, and compliant with safety norms. Established manufacturers also provide warranty and technical support, making them a more reliable choice.

The right distribution board improves electrical safety, performance, and long-term usability. Choosing wisely based on capacity, safety, and material quality ensures a secure and efficient power distribution system for any application.

Installation and Safety Guidelines

Proper installation and maintenance of an electrical DB are essential for preventing electrical hazards and ensuring a safe power supply. Whether for homes, offices, or industrial facilities, following these safety measures helps maintain the use of distribution board effectively.

1. Choose the Right Location

A distribution board should be installed in a dry, well-ventilated area, away from moisture, heat, and direct sunlight. It must be easily accessible for maintenance, yet out of reach of unauthorized individuals or children.

2. Ensure Proper Grounding

Grounding is a critical step in electrical safety. A properly grounded electrical DB prevents the risk of electric shocks and short circuits. Always verify that neutral and earth connections are installed according to safety standards.

3. Use High-Quality Components

All parts, including circuit breakers, busbars, and RCDs, should meet industry safety regulations. Using low-quality or substandard components can increase the risk of electrical failures and fires.

4. Follow Load Distribution Rules

Overloading a distribution board can lead to circuit damage and overheating. Always calculate the power demand and distribute circuits evenly to avoid excess load on any single breaker.

5. Secure Wiring and Connections

Loose or poorly connected wires can lead to sparks and short circuits. Ensure that all wiring is properly insulated, secured, and arranged neatly inside the electrical DB.

6. Label Each Circuit

Clearly labeling each circuit in a distribution board makes it easier to identify power sources and troubleshoot electrical issues. It also helps during emergencies or maintenance work.

7. Perform Regular Maintenance

Routine inspections help detect faulty breakers, loose connections, or signs of wear. A qualified electrician should check the distribution board periodically to ensure everything is in working condition.

8. Hire a Professional for Installation

Unless you are a trained professional, installing a distribution board on your own is not recommended. Always consult a licensed electrician to ensure the installation meets safety codes and regulations.

Following these installation and safety guidelines ensures the use of distribution board remains secure and efficient for long-term operation. Proper maintenance also reduces the chances of electrical failures and hazards.

Common Issues and Troubleshooting

A distribution board plays a crucial role in managing electrical power, but like any system, it can develop problems over time. Recognizing these issues early and knowing how to fix them ensures that an electrical distribution board continues to function safely and efficiently.

1. Overloading

Problem: When too many appliances or circuits draw power beyond the board’s capacity, it can lead to overheating, tripped breakers, or potential fire hazards.

Solution:

- Check if the circuit breakers trip frequently this is a sign of overloading.

- Redistribute electrical loads across different circuits.

- Upgrade to a higher-capacity distribution board if the power demand has increased.

2. Frequent Tripping of Circuit Breakers

Problem: If breakers trip often, it could be due to a faulty appliance, a short circuit, or a power surge.

Solution:

- Unplug all connected devices and reset the breaker.

- If the breaker trips immediately, there may be a short circuit or wiring fault—consult a professional electrician.

- Inspect for damaged wires or loose connections.

3. Short Circuits

Problem: A short circuit occurs when a hot wire comes into contact with a neutral or ground wire, causing an electric surge that trips the breaker.

Solution:

- Look for burnt outlets, a burning smell, or sparking appliances—these indicate a short circuit.

- Replace damaged wires or faulty electrical connections.

- Use high-quality components in the electrical distribution board to prevent future failures.

4. Loose Connections

Problem: Poorly connected wires inside a distribution board can cause power fluctuations, intermittent failures, and overheating.

Solution:

- Tighten all electrical connections inside the distribution board.

- Ensure proper insulation to prevent arcing or sparks.

- Schedule routine maintenance to detect loose wiring early.

5. Buzzing or Humming Sounds

Problem: A humming noise from the distribution board could mean a faulty breaker, loose wiring, or an overloaded transformer.

Solution:

- Identify the source of the noise and check for loose components.

- Replace any worn-out or failing breakers.

- If the issue persists, contact an electrician to inspect the system.

6. Corrosion and Moisture Damage

Problem: Exposure to moisture or humidity can corrode the metal components inside a distribution board, leading to poor connections and electrical failures.

Solution:

- Install the distribution board in a dry, well-ventilated location.

- Use weatherproof enclosures in areas prone to moisture exposure.

- Regularly inspect for signs of rust or water damage.

7. Power Fluctuations

Problem: Sudden dimming or flickering lights and unstable power supply can indicate an issue with load balancing or faulty wiring.

Solution:

- Check if certain circuits are drawing more power than others.

- Ensure proper grounding and use surge protectors to stabilize voltage.

- Have an electrician inspect and balance the electrical loads.

Regular maintenance, timely upgrades, and professional inspections help keep a distribution board in optimal condition, ensuring safe and reliable power distribution.

Conclusion

Understanding what a distribution board is essential for maintaining a safe and efficient electrical system. Whether in homes, offices, or industries, a well-installed electrical DB ensures stable power distribution, protects against electrical hazards, and allows for proper load management.

From circuit breakers and busbars to enclosures and grounding systems, each component plays a role in ensuring safety and reliability. Selecting the right distribution board requires considering factors like load capacity, material quality, and compliance with electrical safety standards.

For proper installation and maintenance, it is always recommended to seek help from a qualified electrician. A professionally installed electrical DB reduces the risk of short circuits, overloading, and equipment failures, ensuring long-term safety and efficiency.

Choosing a high-quality distribution board and following best practices for installation helps keep electrical systems secure and functional for years to come.

FAQs

Q1: What is a distribution board, and what does it do?

Ans: A distribution board is an essential part of an electrical system that distributes power from the main supply to different circuits. It ensures that each circuit receives the required electricity while protecting against overloads and faults using circuit breakers, fuses, and safety devices.

Q2: How many types of distribution boards are there?

Ans: There are different distribution board types, including:

- Main Breaker Panel: Controls the overall power supply in a building.

- Subpanel: Extends power distribution from the main panel.

- Fuse Box: Uses fuses instead of circuit breakers for protection.

- Industrial Distribution Board: Designed for heavy electrical loads in industrial settings.

- Power Distribution Unit (PDU): Used in IT and data centers for server power management.

Q3: What are the key components of a distribution board?

Ans: A distribution board consists of several key parts, including:

- Circuit breakers: Protect circuits from overloads and short circuits.

- Busbars: Conduct electricity between different components.

- Residual Current Devices (RCDs): Prevent electric shocks.

- Main switch: Controls the entire electrical supply.

- Enclosure: Provides protective housing for all components.

Q4: How do I choose the right distribution board for my home or business?

Ans: Choosing the right distribution board depends on:

- Power load: Determine the required capacity based on electrical demand.

- Safety features: Look for circuit breakers, surge protectors, and RCDs.

- Material quality: Choose fire-resistant, corrosion-proof enclosures.

- Compliance with standards: Ensure it meets national and international safety regulations.

- Future expansion: Consider a scalable model for future electrical upgrades.

Q5: What safety precautions should be taken while installing a distribution board?

Ans:

- Install the distribution board in a dry, accessible location.

- Ensure proper grounding to avoid electric shocks.

- Use high-quality components to prevent malfunctions.

- Distribute loads evenly to prevent overheating and circuit trips.

- Always hire a qualified electrician for installation.

Q6: What are the common problems with distribution boards?

Ans: Common issues include:

- Overloading: Too many devices connected, leading to circuit trips.

- Short circuits: Faulty wiring or damaged insulation.

- Loose connections: Can cause power fluctuations or overheating.

- Buzzing sounds: Indicates a failing circuit breaker.

- Moisture damage: Corrosion leading to system failures.

Q7: Can I install a distribution board by myself?

Ans: No, installing a distribution board requires professional expertise. Improper installation can lead to electrical hazards, short circuits, and compliance issues. It is always recommended to hire a licensed electrician to ensure safety and adherence to electrical standards.

Q8: How often should a distribution board be maintained?

Ans: A distribution board should be inspected at least once a year. Regular maintenance checks help detect:

- Loose wiring

- Signs of overheating

- Faulty breakers

- Moisture or corrosion damage

Timely maintenance ensures safety and long-term efficiency.

Q9: What is the difference between a distribution board and an electrical panel?

Ans: An electrical panel is a broader term that refers to any enclosure containing electrical circuits, circuit breakers, or switches. A distribution board is a type of electrical panel specifically designed to distribute power to multiple circuits while ensuring protection against overloads and faults.

Q10: Are there specific regulations for distribution board installations in India?

Ans: Yes, distribution board installations in India must comply with BIS (Bureau of Indian Standards) and IS (Indian Standards) guidelines. Industrial setups must also follow IEC (International Electrotechnical Commission) regulations to ensure electrical safety and legal compliance.