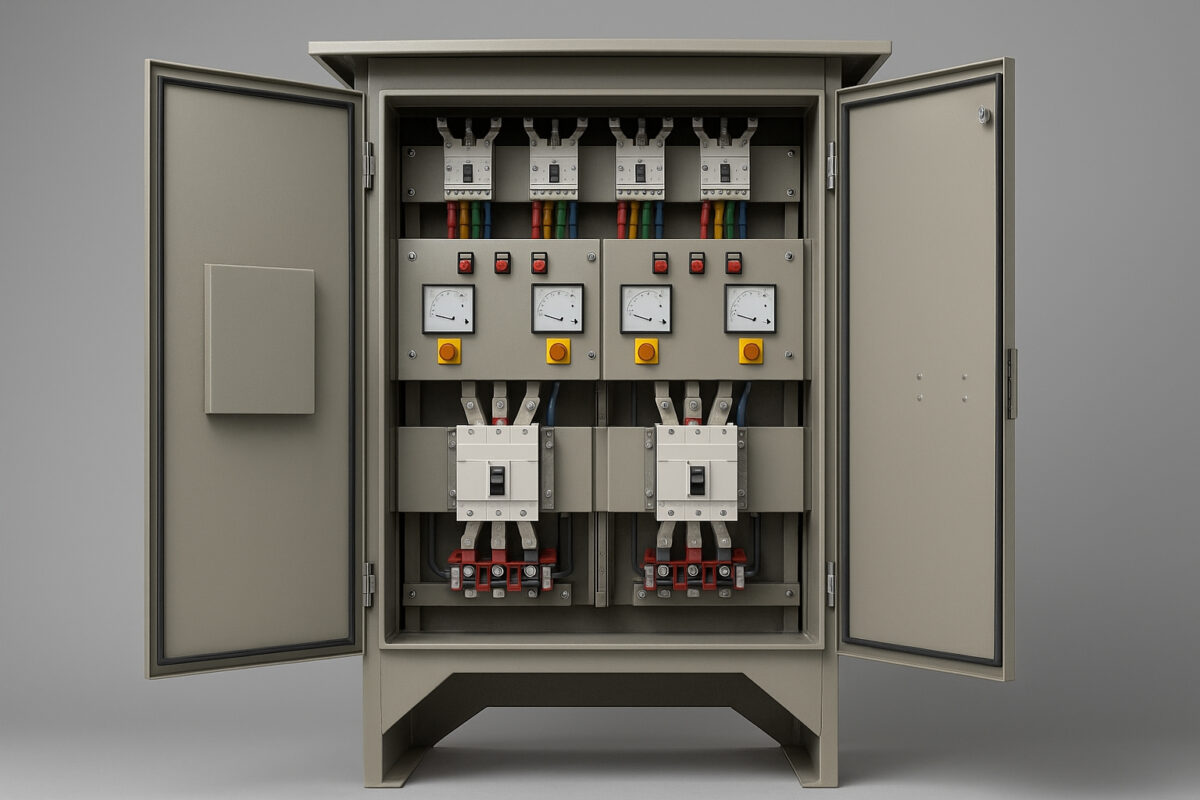

FEEDER PILLAR PANEL

FEEDER PILLAR PANEL

Key Features:

- Weatherproof Enclosure: Designed to protect internal components from dust, moisture, and extreme weather.

- Circuit Breakers: Provides overcurrent and short-circuit protection.

- Bus Bars: Facilitates efficient power distribution across multiple circuits.

- Customizable Configurations: Can be tailored to suit different voltage levels and power capacities.

Applications:

- Street lighting

- Outdoor event power supply

- Industrial and residential complexes

A Feeder Pillar Panel plays a central role in managing electrical power distribution in environments where reliable and secure power handling is non-negotiable. Typically placed outdoors, it serves as a critical interface between the main supply and multiple outgoing circuits. Unlike basic distribution boards, these panels are built to meet higher performance standards, ensuring operational continuity even in the most demanding applications

Practical Functions Beyond Basic Distribution

A feeder pillar panel is more than just a junction box. Its engineering allows it to:

- Isolate and control different sections of a power network

- House switching and protection components like MCBs or MCCBs for each outgoing feeder

- Serve as an inspection and maintenance point without shutting down the entire system

Built for Operational Reliability in Indian Conditions

Dust accumulation :

Panels are designed with IP-rated enclosures that resist particle ingress, particularly in open or semi-enclosed areas.

Configuration Flexibility and Customisation

Whether the site requires 4, 6, 8, or more outgoing feeders, the panel can be assembled to suit your exact usage load and redundancy requirements. It’s also possible to design them for dual incomer systems, enhancing the power availability in critical operations.

Multiple voltage levels

Different current ratings per feeder

Single or three-phase supply types

Integration with automation or remote monitoring devices

Importance of Material and Component Selection

Material choices significantly affect the longevity and performance of a feeder pillar panel. Industrial-grade panels typically use:

- Powder-coated CRCA steel or stainless steel enclosures for corrosion resistance

- Copper or aluminum bus bars sized according to load conditions and thermal limits

- Insulated cable entry glands and structured wiring layouts to reduce short-circuit risk

Maintenance Accessibility and Safety Considerations

Ease of access for inspection and repairs is an often-overlooked design priority. Feeder pillar panels built for maintenance efficiency feature:

Hinged doors with secure locking systems

Clear labeling and cable routing to avoid confusion during service

Removable side or rear

panels

Lifecycle Value and Cost Efficiency

Investing in a well-designed feeder pillar panel may involve a higher upfront cost, but the return is seen in:

- Reduced breakdown incidents

- Minimal maintenance downtime

- Longer lifespan of internal components

- Lower energy losses due to efficient busbar layouts

Compatibility with Modern Power Systems

Modern infrastructure often includes automation, energy metering, and load analytics. Feeder pillar panels can be integrated with: