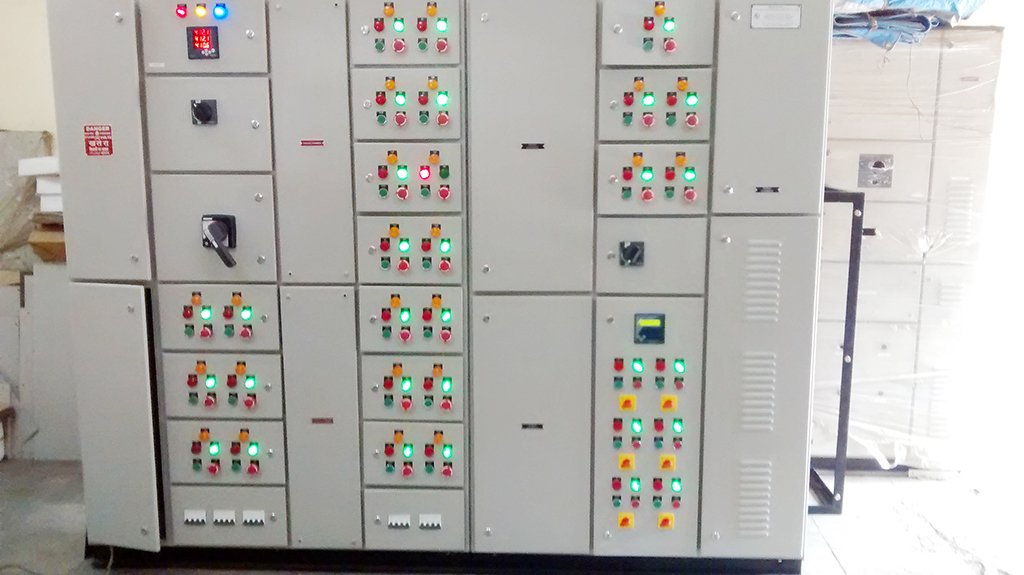

MCC PANELS

MCC PANELS

- IS Standard : IS 8623

- Rated Current : Upto 10,000A

- System : 3ph 4wire

- IP Protection : IP42 / IP52 / IP54 / IP55 / IP 65

- Busbars: Allminium / Tinned copper.

- Short circuit withstand capacity : 65 ka

- Types of installation: Indoor/ Outdoor.

- Additional features:

- Interlocking thru hardwire or PLC for both auto & manual mode .

- Status signals for BMS

- Future interlocks.

An MCC panel, or Motor Control Center panel, is a important component in modern industrial operations. It is designed to house and manage motor control units, making it an essential system for ensuring efficient and safe control of electrical motors across various industries.

What is an MCC Panel?

MCC vs PCC: What’s the Difference?

MCC Panel

PCC Panel

Features of MCC Panels

- Centralized Motor Control

- MCC panels allow multiple motors to be controlled and monitored from a single location, simplifying operations and reducing manual effort.

- MCC panels are designed with a modular structure, making it easy to add, remove, or replace motor units. This scalability supports evolving operational needs in industries like pharmaceuticals and food processing.

- Overload and Short Circuit Protection

- Equipped with advanced protective devices like circuit breakers and overload relays, MCC panels ensure motors are safeguarded from electrical faults, minimizing downtime and preventing damage.

- Modular Design

- MCC panels are designed with a modular structure, making it easy to add, remove, or replace motor units. This scalability supports evolving operational needs in industries like pharmaceuticals and food processing.

- Compact and Space-Saving

- The compact design of MCC panels saves valuable floor space while providing maximum functionality, which is ideal for industries with limited installation areas.

- Customization Options

- Modern MCC panels can be customized to suit specific industrial needs. From panel layout to load capacity, a trusted MCC panel manufacturer can tailor the panel to meet your unique requirements.

- Enhanced Safety Standards

- MCC panels are built to comply with safety regulations, ensuring reliable performance in hazardous environments such as chemical plants and refineries.

- Automation Integration

- Many MCC panels are compatible with automation systems, allowing seamless integration into advanced industrial setups for better control and monitoring.

- Energy Efficiency

- By optimizing motor operations, MCC panels reduce energy consumption, contributing to lower operational costs and a smaller environmental footprint.

- User-Friendly Interface

- Modern MCC panels are equipped with intuitive controls and clear labeling, making them easy to operate and maintain.

- High Durability

- Constructed using premium-grade materials, MCC panels are designed to withstand harsh industrial environments, ensuring long-term reliability.

Key Benefits of MCC Panels

Cost-Effective Solutions

Applications of MCC Panels Across Industries

- Refineries

- In refineries, where processes like distillation and cracking require precise motor control, MCC panels ensure smooth and uninterrupted operations.

- These panels manage the motors driving pumps, compressors, and fans, which are critical to refining processes. With the support of a trusted MCC panel manufacturer in India, refineries can customize panels to meet their unique requirements, ensuring safety and productivity.

- Chemical Plants

- Chemical plants often operate in hazardous environments, requiring robust systems for motor control. MCC panels provide centralized control, enabling plant operators to monitor and regulate motors driving mixers, agitators, and conveyors.

- A reliable MCC panel supplier ensures panels are designed with advanced protection mechanisms, reducing risks and maintaining compliance with safety standards.

- Food and Beverage Processing Units

- In the food and beverage industry, MCC panels are essential for automating conveyor belts, mixers, and packaging machines. Their centralized design simplifies the management of multiple motors, improving efficiency and reducing downtime. For businesses in urban hubs, sourcing from an MCC panel manufacturer in Mumbai ensures timely availability and tailored solutions to meet industry-specific needs.

- Cost Efficiency and Scalability

- Whether in a refinery or a food processing unit, the MCC panel price in Mumbai is an investment that pays off through reduced energy consumption, streamlined operations, and extended motor lifespan. Industries benefit from the ability to scale systems as operations grow, ensuring long-term flexibility and cost savings.

- MCC panels play a vital role in enhancing operational efficiency, ensuring safety, and supporting automation in critical industries. Their adaptability and performance make them a preferred choice for businesses seeking reliable motor control solutions.

Factors to Consider When Choosing an MCC Panel

Customization

Evaluating MCC Panel Prices

Scalability and Future-Proofing

Choosing a Trusted Supplier

Quality and Durability

Compliance with Safety Standards

MCC Panel Price in India

Factors Influencing MCC Panel Price

Manufacturer and Supplier

Choosing a reputable MCC panel manufacturer in India ensures quality but may come with slightly higher costs. A reliable MCC panel supplier in Mumbai like DJ Electro Controls provides value for money with certified products and excellent after-sales support.

Price Range

On average, the MCC panel price in Mumbai or across India can range from ₹50,000 to ₹5,00,000 or more, depending on the specifications and scale of the project. For accurate pricing, it’s best to consult a trusted supplier like DJ Electro Controls, who can provide a quote based on your specific requirements.

Why DJ Electro Controls is the Right Choice for MCC Panels

Expertise in MCC Panel Manufacturing

Customization Options

Frequently Asked Questions

Q1. What is the full form of MCC panel in electrical systems?

Q2. What is the difference between PCC and MCC panels?

Q3. How do MCC panels improve industrial safety?

Q4. What is the price of an MCC panel in Mumbai?

Q5. How do I choose a reliable MCC panel supplier?

Q6. Can MCC panels be customized for specific industries?

Q7. What are the key features of an MCC panel?

- Centralized motor control

- Overload and fault protection

- Scalability for growing operations

- Compliance with safety standards These features ensure efficiency, safety, and adaptability in industrial environments.

Contact Us for Your MCC Panel Needs

Our team of experts is ready to assist you with:

- Designing and customizing MCC panels to suit your operational needs.

- Offering competitive pricing and timely delivery.

- Providing after-sales support to ensure optimal performance.