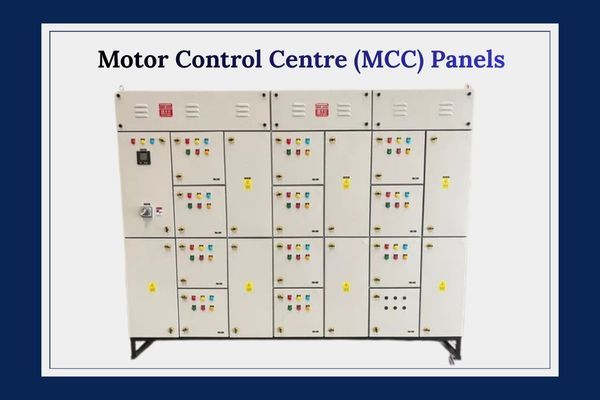

Motor Control Centre (MCC) Panels: Importance and Functionality

Motor Control Centre (MCC) Panels play a major role in how industries manage electric motors safely and efficiently. From small production units to large infrastructure facilities, motors handle pumping, lifting, compressing, mixing and many other operations. Managing these motors individually soon becomes complex, unsafe and time consuming. This is where Motor Control Centre (MCC) Panels become essential.

This blog explains MCC panel basics in a clear and practical way. It focuses on what MCC panels are, how they work, why they are important, and where they are used. The aim is to help engineers, plant owners, purchase teams and even non technical readers understand MCC panels without confusion.

Understanding Motor Control Centre (MCC) Panels

A motor control centre panel is a centralised assembly that controls and protects multiple electric motors from one location. Instead of installing separate starters and protection devices near each motor, everything is arranged inside a single panel system.

This structure makes operation simpler, reduces wiring complexity, and improves safety inside industrial electrical systems.

What is motor control centre panel

When people ask what is motor control centre panel, the simplest answer is that it is a panel designed to start, stop, protect and monitor motors used in industrial processes. Each motor feeder inside the MCC panel has its own control and protection devices, while the incoming power supply is shared through a common busbar system.

MCC panels are generally used where several motors operate together, such as conveyors, pumps, compressors, fans and mixers.

MCC Panel Basics Explained

MCC panel basics revolve around three main purposes. Power distribution, motor control, and protection. All three functions work together to keep motors running smoothly while reducing electrical risks.

Unlike ordinary distribution panels, MCC panels are built specifically for motor loads. Motors draw high starting current and face frequent switching. MCC panels are designed to handle these conditions without affecting system stability.

Motor Control Centre Working Principle

The motor control centre working principle is based on centralised control and sectionalised protection.

Incoming electrical power enters the MCC panel through a main incomer section. From there, power flows through busbars that distribute electricity to individual motor feeders. Each feeder controls one motor or a group of motors.

When an operator presses the start command, the control circuit energises the contactor. This allows power to flow from the busbar to the motor through protective devices. If any fault occurs, such as overload or short circuit, the protection device interrupts the supply to prevent motor damage.

This method allows operators to manage several motors safely from a single location.

Main Components Inside Motor Control Centre (MCC) Panels

Understanding the internal parts helps users know why MCC panels offer better safety and control.

Power Section

The power section includes the main incomer, busbars, and outgoing feeders. Busbars are usually made of copper or aluminium and are sized based on current rating and fault level.

Motor Starters

Motor starters control how motors start and stop. These may include direct online starters, star delta starters, soft starters or variable frequency drives depending on motor capacity and application needs.

Protection Devices

Protection devices guard motors and cables against electrical faults. These devices disconnect the motor supply during overload, short circuit, phase failure or voltage imbalance.

Control Section

The control section manages command signals. It may include push buttons, selector switches, relays and indicators. In automated systems, PLC based control is also used.

Functions of Motor Control Centre Panel

The functions of motor control centre panel go beyond simple switching. MCC panels support daily operations in demanding industrial conditions.

One major function is safe motor starting. Motors draw high current during startup, and MCC panels manage this load without disturbing other equipment.

Another function is fault isolation. When a fault occurs in one motor, the rest of the system continues operating, which prevents complete plant shutdown.

MCC panels also support operational monitoring. Operators can quickly identify which motor is running, stopped or facing an issue.

Maintenance becomes easier since all controls are placed at one location rather than spread across the facility.

Types of Motor Control Centre Panels

MCC panels are designed in different formats based on application and maintenance needs.

Fixed Type MCC Panels

In fixed type panels, all components are permanently mounted. These panels suit small and medium installations where downtime during maintenance is acceptable.

Draw Out MCC Panels

Draw out MCC panels allow individual feeders to be removed without shutting down the entire panel. This design supports quicker maintenance and improved safety.

Intelligent MCC Panels

Intelligent MCC panels include communication enabled devices. These panels support remote monitoring, fault alerts and data logging, which suits advanced industrial automation setups.

Motor Control Centre (MCC) Panels in Industrial Automation

MCC panel in industrial automation acts as the backbone for motor driven processes. Automated plants depend on accurate motor control for productivity and quality.

Integration with PLC systems allows automatic start stop sequences, interlocks, and safety logic. Sensors and feedback devices communicate with the MCC panel to maintain stable operations.

Automation reduces manual intervention and supports consistent output across production cycles.

Industries We Serve

Motor Control Centre (MCC) Panels are used across a wide range of industries. Their flexibility allows them to suit different operational needs.

MCC Panel for Manufacturing Plants

Manufacturing units use MCC panels to control conveyors, mixers, compressors and machine tools. Centralised control helps maintain production flow and simplifies maintenance planning.

MCC Panel for Power Plant

In power plants, MCC panels manage auxiliary motors such as cooling pumps, fans and fuel handling systems. Stable motor control supports continuous power generation.

MCC Panel for Water Treatment Plant

Water treatment facilities depend on pumps and blowers. MCC panels provide safe control and protection, helping maintain uninterrupted water supply and treatment processes.

MCC Panel for Oil and Gas Industry

Oil and gas operations demand high reliability. MCC panels support pumps, compressors and processing equipment under demanding conditions.

MCC Panel for Process Industries

Chemical, cement, food and pharmaceutical industries rely on MCC panels for controlled motor operation that matches process requirements.

Selection Factors for Motor Control Centre Panels

Choosing the right MCC panel involves understanding load requirements, operating environment and future expansion plans.

- Motor ratings determine starter type and protection selection.

- Environmental conditions influence enclosure type.

- Operational needs guide automation and monitoring features.

- Compliance with IEC standards ensures safe operation.

Working with experienced manufacturers such as Dj Electro Controls supports correct design and dependable performance.

Role of Dj Electro Controls in MCC Panel Manufacturing

Dj Electro Controls focuses on manufacturing MCC panels that match industrial requirements and Indian operating conditions. Attention is given to component selection, wiring practices and panel layout.

Panels are designed to support stable motor operation, ease of use and long service life. This approach supports industries looking for reliable electrical control solutions.

Comparison of MCC Panel Types

| Feature | Fixed Type MCC | Draw Out MCC | Intelligent MCC |

| Maintenance | Panel shutdown required | Individual feeder removal | Remote diagnostics |

| Initial cost | Lower | Moderate | Higher |

| Suitability | Small plants | Medium to large plants | Automated facilities |

Common Applications of MCC Panels

| Industry | Typical Motors Controlled |

| Manufacturing | Conveyors, mixers |

| Power plants | Pumps, fans |

| Water treatment | Pumps, blowers |

| Oil and gas | Compressors |

| Process industries | Agitators |

Final Thoughts

Motor Control Centre (MCC) Panels remain an essential part of industrial electrical systems. They bring order, safety and control to environments where multiple motors operate together. By understanding their working principle, functions and applications, industries can make informed decisions that support stable operations and long term performance.

Organisations planning new installations or system upgrades benefit from well designed MCC panels that match their process needs. Working with experienced manufacturers helps achieve dependable motor control solutions that support daily operations without unnecessary complexity.

To know more about suitable MCC panel configurations for your facility, connecting with a trusted panel manufacturer such as Dj Electro Controls can support better planning and reliable execution.

Frequently Asked Questions

Q1. What is the main purpose of Motor Control Centre (MCC) Panels?

Answer: The main purpose is to control, protect and monitor multiple motors from one central location. This improves safety and operational efficiency.

Q2. How does a motor control centre panel differ from a distribution panel?

Answer: A distribution panel supplies power to loads, while an MCC panel is designed specifically for motor control with starters and protection devices.

Q3. Are MCC panels suitable for small industries?

Answer: Yes. MCC panels can be designed for both small and large facilities based on motor quantity and ratings.

Q4. What standards apply to MCC panels in India?

Answer: Most MCC panels follow IEC standards along with relevant Indian electrical codes for safety and performance.

Q5. How does an MCC panel improve maintenance?

Answer: Centralised layout allows technicians to identify and isolate faults quickly without tracing cables across the plant..