What is Feeder Pillar

Introduction

A feeder pillar is an essential component in electrical distribution systems that acts as a central hub for managing and distributing power. Simply put, when people ask, “what is a feeder pillar?”, the answer is that it’s an outdoor cabinet that houses circuit breakers, fuses, and electrical switches, providing a safe and organized way to control electricity flow to different areas.

What is a Feeder Pillar?

A feeder pillar is a essential part of an electrical power distribution system. When people ask, “what is a feeder pillar?”, they’re referring to a weatherproof enclosure that acts as a control point for managing and distributing electricity.

It functions as a secure hub that houses electrical components like circuit breakers, fuses, and isolators, ensuring that electricity is safely distributed to various circuits without overloading the system.

In simple terms, a feeder pillar panel works as a bridge between the main power supply and multiple end circuits. The main power line connects to the feeder pillar, which then distributes that power to different areas through separate circuits.

Each circuit within the feeder pillar panel can be controlled and isolated independently, which simplifies maintenance and enhances safety.

The core function of a feeder in electrical power system is to ensure that electricity flows efficiently and safely from the main source to the endpoints, such as buildings, streetlights, or industrial machinery. Without a feeder pillar, managing and distributing power to different areas would be complicated and risk-prone.

One of the key advantages of using a feeder pillar is the flexibility it offers in power distribution. Electricians can control power flow to specific sections without shutting down the entire system. This makes it easier to perform maintenance, repairs, or upgrades without causing widespread outages.

In electrical feeder systems, safety is paramount. A feeder pillar includes protective devices like circuit breakers and fuses that prevent issues like short circuits or power surges, protecting both the electrical infrastructure and connected devices.

Whether in an industrial setting, a commercial complex, or even for outdoor installations like streetlights, feeder pillars play a vital role in ensuring a stable and efficient power distribution network.

Components of a Feeder Pillar

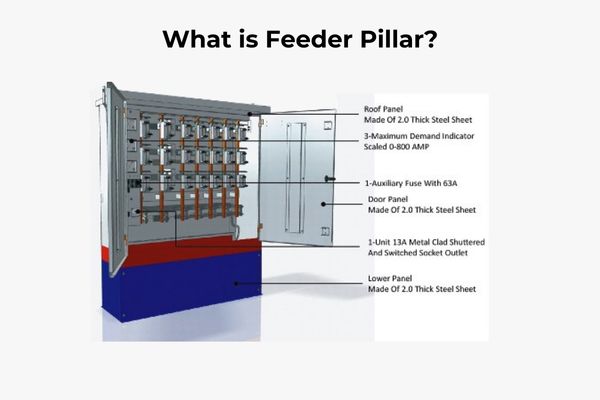

A feeder pillar box is made up of several essential components that work together to ensure safe and efficient power distribution. Each part plays a specific role in managing electricity and maintaining system reliability. Below are the key components found in a feeder pillar and why they are essential.

1. Enclosure

The enclosure is the outer casing of the feeder pillar box. Designed to be weatherproof and durable, it protects the internal components from external elements like rain, dust, and extreme temperatures. This ensures the system remains safe and operational, even in outdoor environments. The enclosure also acts as a physical barrier, preventing unauthorized access to live electrical parts, which enhances safety.

2. Busbars

Busbars are metallic strips or bars within the pillar panel that conduct electricity throughout the system. They serve as the main pathway for electrical current, distributing power to multiple circuits. Busbars are designed to handle high levels of current, ensuring efficient power flow with minimal energy loss. Their layout within the feeder box allows for easy connections to various circuits.

3. Circuit Breakers

Circuit breakers are critical for maintaining safety in any power distribution system. Located within the feeder pillar box, they automatically cut off the power supply in case of overloads or short circuits.

This prevents damage to electrical equipment and reduces the risk of fire or other hazards. Circuit breakers can also be manually operated during maintenance or system upgrades.

4. Switches and Fuses

Switches in the feeder pillar allow operators to control the flow of electricity to specific circuits. This makes it easy to isolate areas for maintenance or in case of faults. Fuses serve as an additional layer of protection by breaking the circuit if the current exceeds safe levels, safeguarding both the system and connected devices.

5. Protection Relays

Protection relays monitor the electrical system for irregularities like voltage spikes, current imbalances, or frequency changes. If any abnormal condition is detected, the relay triggers the circuit breakers to shut off the power supply. This automatic response helps prevent major electrical failures and enhances overall system reliability.

Importance of These Components

Every part of a feeder pillar plays a role in maintaining safety and system efficiency. The enclosure protects the internal components, while the busbars ensure smooth power distribution. Circuit breakers, switches, fuses, and protection relays work together to safeguard the system from faults, preventing equipment damage and ensuring uninterrupted power supply.

A well-designed feeder pillar box with these components not only ensures reliable power distribution but also enhances safety for both the infrastructure and the people working with it.

By incorporating the right safety features in feeder pillar systems, the risk of electrical hazards is significantly reduced, making these units an essential part of any power distribution network.

Types of Feeder Pillars

Feeder pillars come in various types, each designed to meet specific electrical distribution needs. Whether it’s for outdoor, indoor, low-voltage, or high-voltage applications, there is a feeder pillar tailored for every situation. Understanding the different types and their use cases helps in selecting the right pillar box electrical system for specific environments.

1. Outdoor Feeder Pillar

An outdoor feeder pillar is built to withstand harsh weather conditions. Its robust enclosure is usually made from materials like stainless steel or weatherproofed metal to protect internal components from moisture, dust, and extreme temperatures. These pillars are commonly installed in public spaces, such as parks, street lighting networks, and industrial complexes.

The best outdoor feeder pillar for industrial use offers additional protection against environmental hazards, ensuring continuous power distribution without interruptions. Their design often includes enhanced locking mechanisms to prevent unauthorized access, making them a reliable choice for exposed locations.

2. Indoor Feeder Pillar

An indoor feeder pillar is designed for environments where exposure to external elements is minimal. Typically found in commercial buildings, factories, and warehouses, these pillars focus more on functionality and safety than weather resistance.

Since they are housed in controlled environments, indoor feeder pillars often have a simpler design compared to their outdoor counterparts. Despite this, they still offer complete protection for power distribution and are equipped with circuit breakers, switches, and fuses to manage internal electrical networks safely.

3. Low-Voltage vs. High-Voltage Feeder Pillars

Feeder pillars can also be classified based on the voltage levels they manage:

- Low-Voltage Feeder Pillars:

These are typically used in residential areas, small commercial buildings, and light industrial applications. They handle lower voltage levels and are designed to safely distribute power to lighting circuits, small machinery, and appliances. - High-Voltage Feeder Pillars:

Commonly used in heavy industries, power plants, and large-scale infrastructure projects, these pillars manage higher voltage levels required to power large machinery and extensive electrical systems. Enhanced insulation and robust safety features are critical components in high-voltage feeder pillars to prevent electrical hazards.

4. Customized Feeder Pillars

In some cases, standard feeder pillars may not meet specific operational needs. This is where customized feeder pillars come into play. These units can be tailored to unique requirements, including specialized power distribution components, advanced safety features, or specific enclosure materials.

Customized designs are often used in complex projects such as airports, data centers, or specialized industrial applications where off-the-shelf solutions are insufficient. These pillar box electrical systems are built with the end-user’s requirements in mind, ensuring optimal performance and safety.

Benefits of Using Feeder Pillars

Feeder pillars play an essential role in modern power distribution systems. They offer several advantages that make them essential for industrial, commercial, and public applications. From enhancing safety to improving energy efficiency, here are the key benefits of using a feeder pillar in any electrical feeder setup.

1. Enhanced Safety

One of the primary advantages of using a feeder pillar is the added level of safety it brings to power distribution systems. These units are equipped with circuit breakers, fuses, and protection relays that safeguard against electrical faults such as short circuits, overloads, and surges.

In the event of a fault, these safety features isolate the affected circuits, preventing equipment damage and reducing the risk of electrical fires.

Additionally, the enclosed design of a feeder pillar helps protect personnel by limiting exposure to live electrical components. Lockable doors and durable enclosures add another layer of security, ensuring that only authorized personnel can access the system.

2. Efficient Power Distribution

A well-designed feeder pillar enhances the overall efficiency of an electrical feeder system. By organizing multiple circuits within a single panel, it allows for streamlined power distribution to various locations or devices. This setup reduces energy loss and ensures that power flows smoothly across all circuits.

The clear labeling and structured layout inside the feeder pillar also simplify troubleshooting and maintenance, allowing technicians to quickly identify and address issues without disrupting the entire system.

3. Flexibility in Load Management

Feeder pillars offer flexibility in managing electrical loads, which is particularly valuable in dynamic environments like industrial plants or commercial complexes. Users can easily add, remove, or isolate circuits to accommodate changing power demands without overhauling the entire system.

This flexibility supports load balancing, helping to distribute energy efficiently across different circuits. In turn, it prevents overloading and enhances the reliability of the entire power distribution network.

4. Weather-Resistant Designs

Many feeder pillars are designed with weather-resistant enclosures, making them suitable for both indoor and outdoor use. Outdoor feeder pillars are built to withstand harsh environmental conditions, including rain, dust, and extreme temperatures. These rugged designs ensure that the internal components remain protected and operational, regardless of the external environment.

Weather-resistant feeder pillars are commonly used in applications such as street lighting, parks, and public spaces, where exposure to the elements is unavoidable.

The Value of Feeder Pillars in Power Systems

Incorporating a feeder pillar into an electrical feeder system offers significant advantages in terms of power safety and operational efficiency. From protecting circuits to enabling flexible load management, feeder pillars are essential for maintaining reliable and efficient energy distribution. Their weather-resistant designs further extend their usability across various applications, ensuring consistent performance in even the most demanding environments.

Applications of Feeder Pillars

Feeder pillars play a vital role in ensuring reliable and organized electrical power distribution across various sectors. Whether it’s managing power in large industrial complexes or lighting up public spaces, feeder pillars offer flexibility and safety for different environments. Below are some of the most common applications and how they support electrical distribution in these areas.

1. Industrial Facilities

In industrial settings, managing large amounts of electrical power is essential. A feeder in an electrical power system distributes electricity to heavy machinery, production lines, and control systems within industrial facilities. These feeder pillars ensure stable power delivery, which is critical for maintaining continuous operations and avoiding costly downtimes.

Industrial environments often demand feeder pillars that can handle higher voltages and currents. Features like enhanced circuit protection, durable enclosures, and advanced safety mechanisms are commonly integrated into these units. This setup not only improves industrial power distribution but also safeguards expensive equipment from potential electrical hazards.

2. Commercial Buildings

In commercial buildings such as shopping malls, office complexes, and hospitals, feeder pillars are used to distribute power across multiple floors and departments. They serve as centralized hubs that manage lighting systems, HVAC units, elevators, and other essential services.

A commercial feeder pillar provides a safe and efficient method of managing power in high-traffic areas. By isolating circuits and integrating safety features like circuit breakers and fuses, these units help ensure uninterrupted services while making it easier to perform maintenance without disrupting daily operations.

3. Street Lighting Systems

One of the most visible applications of feeder pillars is in street lighting systems. These units control the power supply to streetlights, traffic signals, and pedestrian crossings, ensuring public safety during night hours.

A feeder is also called a “control cabinet” in street lighting applications. It allows municipal workers to manage large networks of lights, turning them on or off as needed and ensuring proper maintenance. The feeder pillar also protects the lighting circuits from overloads or short circuits, extending the life of the lighting infrastructure.

4. Parks and Public Spaces

In public spaces such as parks, playgrounds, and recreational areas, feeder pillars are used to distribute power to lighting, fountains, kiosks, and other electrical installations. These spaces often require durable, weather-resistant feeder pillars that can withstand exposure to the elements while maintaining consistent power delivery.

In these environments, feeder pillars contribute to public safety and comfort, ensuring that pathways remain illuminated, and facilities operate smoothly. They also support seasonal installations like holiday lights or event-specific electrical setups, offering flexibility for public gatherings and activities.

Supporting Electrical Distribution Across Sectors

Regardless of the setting, feeder pillars serve as the backbone of reliable electrical power distribution. From managing high-energy demands in industrial facilities to supporting daily operations in commercial buildings, their versatility makes them indispensable. In public spaces, they help keep communities safe and functional, ensuring everything from streetlights to park amenities runs smoothly.

By providing centralized control, circuit protection, and efficient power distribution, feeder pillars continue to play an essential role across various sectors, adapting to the unique needs of each application while ensuring safety and reliability.

How to Choose the Right Feeder Pillar?

Selecting the right feeder pillar is essential for ensuring efficient and safe power distribution in any facility. With various options available, making the right choice can seem challenging. However, by focusing on specific factors, businesses can select a feeder pillar that meets their needs and adheres to industry standards.

Here’s a simple guide on how to choose the right feeder pillar for factories, commercial buildings, or public spaces.

1. Power Requirements

The first step in choosing a feeder pillar is understanding the power requirements of the facility. Assess the total load demand, types of machinery or equipment involved, and peak power usage. A feeder pillar should be capable of handling the maximum electrical load without risk of overloading or overheating.

For industrial facilities, where heavy machinery demands high power, selecting a feeder pillar with robust power distribution capabilities is essential. In contrast, commercial buildings may require pillars optimized for lighting, HVAC systems, and smaller electrical loads.

2. Environmental Conditions

The operating environment plays a key role in selecting the right feeder pillar. For outdoor installations, such as street lighting or parks, a weatherproof feeder pillar with high resistance to dust, moisture, and temperature fluctuations is necessary. Materials like stainless steel or powder-coated enclosures provide extra protection against environmental hazards.

For indoor settings, such as factories or commercial complexes, feeder pillars may not need as much weather protection but should still be durable and easy to maintain.

3. Safety Standards

Safety is a critical factor when selecting a feeder pillar. Ensure the unit complies with local and international safety standards, including proper circuit protection, reliable grounding, and the use of high-quality circuit breakers and fuses. A trusted feeder pillar manufacturer in India will typically design products that meet or exceed these safety benchmarks.

Features like lockable enclosures, emergency shut-offs, and fire-resistant materials can enhance the overall safety of the system, protecting both the equipment and personnel.

4. Customization Needs

Every facility has unique power distribution requirements, which is why customization can be valuable. Leading manufacturers offer customized feeder pillars tailored to specific needs, whether it’s additional circuit slots, enhanced safety features, or specialized enclosures.

For businesses with complex electrical setups, consulting with the best electrical panel manufacturer in India ensures that the feeder pillar is built to accommodate specific operational demands.

Tips for Making an Informed Decision

- Work with Reputable Manufacturers: Choose a feeder pillar manufacturer in India with a proven track record of delivering high-quality products. This ensures reliability and adherence to safety standards.

- Consider Future Expansion: Select a feeder pillar that allows room for future scalability. This helps avoid additional costs if your facility’s power needs increase.

- Evaluate Maintenance Needs: Opt for designs that simplify maintenance, including easy access to internal components and clear labeling.

- Focus on Quality Over Cost: While budget considerations are important, prioritizing quality and safety will pay off in the long run, reducing the risk of failures and costly repairs.

Choosing the right feeder pillar is about balancing performance, safety, and adaptability. By considering power requirements, environmental factors, safety standards, and customization options, businesses can invest in a system that ensures reliable and efficient power distribution for years to come.

Installation and Maintenance Guide

Proper installation and maintenance of a feeder pillar panel are essential to ensure safe and efficient power distribution. Following the right steps not only enhances performance but also extends the lifespan of the equipment. This comprehensive feeder pillar installation guide outlines the key steps, best maintenance practices, and tips for troubleshooting common issues.

Step-by-Step Process for Installing a Feeder Pillar

- Site Preparation

Begin by selecting a suitable location for the feeder pillar panel. Ensure the area is flat, accessible for maintenance, and away from potential hazards. For outdoor installations, consider weather protection and ease of cable routing. - Foundation and Mounting

Prepare a concrete base to securely mount the feeder pillar. The base should be level and reinforced to handle the weight and environmental conditions. Anchor bolts are then used to secure the feeder pillar panel to the foundation. - Cable Routing and Connections

Route the incoming and outgoing cables through the designated entry points. Carefully connect the electrical feeder cables to the appropriate terminals, following the wiring diagram provided by the manufacturer. Ensure all connections are tight to prevent energy loss and overheating. - Earthing and Grounding

Proper grounding is essential for safety. Connect the feeder pillar to an effective earthing system to minimize the risk of electrical faults or surges. - Testing and Commissioning

Before powering up, conduct thorough tests to ensure all circuits are correctly connected and functional. Use a multimeter or other testing tools to check for continuity, insulation resistance, and grounding effectiveness.

Best Practices for Regular Maintenance

- Routine Inspections

Schedule regular visual inspections to check for signs of wear, corrosion, or loose connections. Early detection of minor issues can prevent major failures. - Cleaning and Debris Removal

Keep the feeder pillar clean from dust, dirt, and moisture. In outdoor feeder pillars, debris can accumulate inside the panel, leading to overheating or electrical faults. - Check Safety Devices

Regularly test circuit breakers, fuses, and protection relays to ensure they function correctly. Replace any faulty components immediately to maintain system integrity. - Thermal Scanning

Use thermal imaging to detect hotspots within the feeder pillar panel. This technique can help identify overloaded circuits or loose connections before they become serious issues.

Common Issues and How to Troubleshoot Them

- Overheating:

Overheating often results from loose connections or overloaded circuits. Tighten connections and balance the load across multiple circuits to reduce heat buildup. - Moisture Ingress:

Water inside the feeder pillar can cause short circuits. Ensure the enclosure seals are intact and the ventilation is functioning correctly. Use desiccant packs if necessary to absorb moisture. - Tripped Circuit Breakers:

Frequent tripping may indicate an overloaded circuit or a short circuit. Inspect the connected equipment and redistribute the load if needed. - Corroded Terminals:

Corrosion can disrupt electrical connections. Clean affected areas with appropriate contact cleaners and apply anti-corrosion coatings to prevent future issues.

Feeder Pillar Care

Proper installation and ongoing maintenance are critical to the longevity and efficiency of any feeder pillar. By following this feeder pillar installation guide and adhering to regular maintenance schedules, businesses can ensure a safe and reliable power distribution system. These maintenance tips for feeder pillars not only prevent unexpected downtime but also help extend the life of the equipment.

Feeder Pillar Standards and Safety Regulations

Ensuring that a feeder pillar meets established industry standards and safety regulations is essential for maintaining the reliability and safety of any power distribution system. Compliance with these guidelines not only protects equipment and personnel but also ensures that installations meet legal requirements.

Here’s a closer look at the feeder pillar safety standards and the importance of adhering to electrical compliance guidelines.

1. Industry Standards for Feeder Pillars

Feeder pillars are designed and manufactured following strict industry standards to guarantee quality, safety, and performance. Some of the most recognized standards for feeder pillar installations include:

- IS Standards (Indian Standards):

In India, feeder pillars must comply with IS 8623 standards, which cover low-voltage switchgear and control gear assemblies. This ensures that the feeder pillar can safely handle the required electrical loads while offering adequate protection against electrical faults. - IEC Standards (International Electrotechnical Commission):

Globally, IEC 61439 is the key standard governing low-voltage switchgear assemblies, including feeder pillars. It specifies performance criteria, safety measures, and construction requirements, ensuring that products meet international safety and efficiency benchmarks. - IP Ratings (Ingress Protection):

For outdoor feeder pillars, the enclosure must meet specific IP ratings to ensure protection against dust and water. For instance, an IP65 rating indicates that the feeder pillar is dust-tight and protected against water jets, making it suitable for harsh outdoor environments.

These feeder pillar safety standards ensure that the equipment is reliable, durable, and capable of withstanding both electrical and environmental stresses.

2. Safety Regulations and Compliance Guidelines

Adhering to electrical compliance guidelines is essential for the safe operation and longevity of feeder pillars. Regulations focus on several critical areas:

- Circuit Protection:

Safety regulations require that feeder pillars be equipped with proper circuit protection devices, including circuit breakers, fuses, and protection relays. These components help prevent electrical faults like short circuits and overloads, reducing the risk of fires and equipment damage. - Earthing and Grounding:

Proper grounding is mandated to ensure that any fault currents are safely redirected away from equipment and personnel. This reduces the risk of electrical shocks and ensures system stability. - Clearance and Accessibility:

Safety regulations also dictate the necessary clearance around feeder pillars to allow for safe operation and maintenance. Adequate space ensures that technicians can access and service the equipment without exposure to live electrical parts. - Fire and Surge Protection:

Many compliance standards require the inclusion of surge protection devices and fire-resistant materials within the feeder pillar to minimize the risk of fires caused by power surges or faults.

3. Why Compliance is Important

Following safety regulations for feeder pillar installations is not just about legal compliance, it’s about protecting lives, equipment, and infrastructure. Non-compliant installations can lead to serious risks, including electrical fires, equipment failure, and costly downtime.

Moreover, adhering to recognized standards helps ensure system reliability and efficiency. Properly installed and compliant feeder pillars reduce maintenance costs and extend the lifespan of the electrical network.

Businesses that follow electrical compliance guidelines also benefit from smoother inspections and certifications, reducing the risk of legal complications and ensuring adherence to local and international safety laws.

Investing in feeder pillars that meet established safety standards and following proper installation guidelines is essential for the safe and efficient operation of any power distribution system. By prioritizing safety and compliance, businesses can protect their infrastructure, employees, and bottom line while ensuring continuous, reliable power.

Why Choose DJ Electro Controls?

When it comes to high-quality feeder pillars and power distribution solutions, DJ Electro Controls stands out as a trusted name in the industry. As a leading feeder pillar manufacturer in India.

the company has built a reputation for delivering reliable, safe, and customized electrical solutions tailored to a variety of applications across industrial, commercial, and public sectors.

1. Industry-Leading Expertise and Quality

DJ Electro Controls has years of experience in manufacturing premium feeder pillars that meet stringent quality standards. Every product is designed with precision, ensuring it complies with both IS and IEC norms for safety and performance.

The company prioritizes the use of high-grade materials and advanced manufacturing techniques to create durable and efficient feeder pillars that excel in both indoor and outdoor environments.

This dedication to quality has positioned DJ Electro Controls among the best electrical panel manufacturers in India, offering products that customers can rely on for long-term performance.

2. Compliance and Safety Standards

Understanding the importance of safety in power distribution, DJ Electro Controls ensures that every feeder pillar meets established feeder pillar safety standards and adheres to all electrical compliance guidelines.

The company focuses on integrating features such as circuit protection devices, grounding systems, and weather-resistant enclosures to guarantee safe and efficient power management.

Customers can trust that all products are rigorously tested and certified to meet industry requirements, minimizing the risks associated with electrical installations.

3. Custom Solutions to Meet Unique Needs

Every project has its own set of challenges and requirements, and DJ Electro Controls offers customized feeder pillar solutions to match. Whether you need a standard feeder pillar for street lighting or a specialized unit for complex industrial applications, the company works closely with clients to design and manufacture panels tailored to specific operational demands.

This flexibility ensures that businesses get exactly what they need without compromising on safety, efficiency, or quality.

4. Wide Service Coverage Across India

As a prominent feeder pillar supplier in India, DJ Electro Controls serves a wide range of industries and sectors throughout the country. From major metropolitan areas to growing industrial hubs, the company has the infrastructure and expertise to deliver and support feeder pillars across India.

Whether you’re in need of a single unit or a large-scale supply for an infrastructure project, DJ Electro Controls ensures timely delivery and ongoing support to meet your power distribution needs.

Frequently Asked Questions

Q1. What is a feeder pillar and how does it work?

Ans: A feeder pillar is an outdoor or indoor electrical cabinet that serves as a central point for distributing electricity from a main power source to multiple circuits. It houses key components like circuit breakers, fuses, and switches, ensuring safe and efficient power distribution. The primary function of a feeder pillar is to control and manage the flow of electricity to various endpoints while offering protection against faults such as overloads and short circuits.

Q2. Where are feeder pillars commonly used?

Ans: Feeder pillars are widely used across multiple sectors. In industrial facilities, they manage high power loads for machinery and equipment. In commercial buildings, they distribute electricity to lighting, HVAC systems, and elevators. Outdoor feeder pillars are commonly found in street lighting systems, parks, and public spaces, controlling lights and other electrical installations while providing weather-resistant protection.

Q3. What’s the difference between an electrical feeder and a feeder pillar?

Ans; An electrical feeder refers to the cables or conductors that carry power from a source to different distribution points. A feeder pillar, on the other hand, is the enclosure that organizes, protects, and manages these electrical feeders. While the feeder is responsible for transporting electricity, the feeder pillar box serves as the control hub, providing circuit protection and isolation options for safe maintenance and operation.

Q4. How do I choose the right feeder pillar for my business?

Ans: Choosing the right feeder pillar involves evaluating several factors:

- Power Requirements: Determine the total electrical load and select a feeder pillar that can handle peak demands.

- Environmental Conditions: For outdoor applications, opt for weather-resistant outdoor feeder pillars with appropriate IP ratings.

- Safety Standards: Ensure the unit complies with IS/IEC norms and includes essential safety features like circuit breakers and grounding systems.

- Customization Needs: Depending on your operations, consider customized feeder pillars that can be tailored to specific power distribution requirements.

Q5. What safety features should a feeder pillar have?

Ans: A quality feeder pillar should include several safety features to protect both the system and personnel:

- Circuit Breakers and Fuses: To prevent overloads and short circuits.

- Grounding Systems: For safe fault current redirection.

- Lockable Enclosure: To prevent unauthorized access.

- Surge Protection Devices: To shield against voltage spikes.

- Weatherproofing (for outdoor units): To safeguard against dust, moisture, and extreme temperatures.

Q6. Can feeder pillars be customized for specific applications?

Ans: Yes, feeder pillars can be fully customized to meet specific operational needs. Businesses often require customized feeder pillars for unique applications such as specialized industrial equipment, complex lighting systems, or high-power distribution networks. Customizations may include additional circuit slots, enhanced safety features, or tailored enclosures suitable for challenging environments.

Q7. What are the common maintenance practices for feeder pillars?

Ans: Routine maintenance is essential for ensuring the reliability and safety of a feeder pillar. Common maintenance practices include:

- Visual Inspections: Regularly check for corrosion, loose connections, and wear.

- Cleaning: Remove dust, debris, and moisture, especially for outdoor feeder pillars.

- Testing Safety Devices: Ensure circuit breakers, fuses, and relays function correctly.

- Thermal Scanning: Detect hotspots that could indicate overloaded circuits.

- Cable Tightening: Secure all connections to prevent energy loss and overheating.

Q8. How does an outdoor feeder pillar differ from an indoor one?

Ans: The primary difference lies in the design and environmental protection features. An outdoor feeder pillar is built with a weatherproof enclosure, often with a high IP rating, to withstand dust, moisture, and varying temperatures. It typically includes additional safety features to guard against environmental damage. In contrast, indoor feeder pillars focus more on efficient power distribution within controlled environments, without the need for extensive weatherproofing.

Q9. Are there industry standards for feeder pillar installations?

Ans: Yes, feeder pillar installations must comply with both national and international safety standards. In India, IS 8623 outlines requirements for low-voltage switchgear and control gear assemblies. Globally, IEC 61439 is the key standard governing feeder pillar designs. Compliance with these standards ensures that the feeder pillar meets safety, performance, and durability benchmarks.

Q10. What is the average cost of installing a feeder pillar?

Ans: The cost of installing a feeder pillar can vary widely based on several factors:

- Type and Size: A basic feeder pillar box for small applications will cost less than a large, complex unit designed for industrial use.

- Customization Needs: Tailored feeder pillars with specific features or enhanced safety measures will increase the overall cost.

- Installation Complexity: Sites requiring extensive groundwork or complex wiring may incur higher installation fees.

- Location: Local labor rates and material availability can also influence the final cost.

On average, prices can range from moderate to high, depending on these variables. It’s advisable to consult with a reputable feeder pillar manufacturer for an accurate quote.

Conclusion

Understanding what a feeder pillar and its role in modern electrical systems is essential for businesses and industries looking to maintain efficient and safe power distribution. A feeder pillar serves as a vital hub, ensuring that electricity flows smoothly while safeguarding equipment and personnel from potential electrical hazards.

Choosing the right feeder pillar depends on several factors, including power requirements, environmental conditions, and safety standards. Whether it’s an outdoor feeder pillar built to withstand harsh weather or a customized feeder pillar tailored for specific industrial needs, selecting the right system ensures reliable energy distribution and long-term performance.

For businesses seeking high-quality, durable, and compliant feeder pillars, DJ Electro Controls is a trusted partner. As a leading feeder pillar supplier in India, the company offers a wide range of standard and custom solutions designed to meet diverse electrical distribution needs.

With a strong focus on quality, safety, and customer satisfaction, DJ Electro Controls ensures that every product aligns with industry standards and provides long-lasting performance.

If you’re in need of expert advice or looking for a feeder pillar that perfectly fits your specific requirements, don’t hesitate to reach out to DJ Electro Controls. Their team of professionals will guide you through the selection process and offer customized solutions tailored to your project’s unique needs.